Industrial IoT: Making products smart

Meier Tobler AG:

«Our heat pumps needed to get on the Internet.»

Meier Tobler is making service of heat pumps more efficient with remote diagnostics and remote maintenance using an IoT platform. And customers no longer have to look after their heating system.

Text: Urs Binder, images: Luca Zainer,

The heating industry is undergoing radical change. For Andreas Plüer and Thomas Grolp from Meier Tobler (Klima Schweiz) AG, this is crystal clear: The share of fossil-fuel heating systems is in decline, while the use of heat generators from renewable energy is rising. It is already the case that some 80 per cent of new buildings are being equipped with heat pumps instead of fossil-fuel heating systems, and this trend is accelerating. This is not a good thing for the classic service business: Heat pumps are considered maintenance-free. Customers tend to forego a service agreement, in contrast to oil or gas heating. “Over time, however, many characteristics of a newly built house change; more people move in, humidity decreases, and the requirements for the heating system change,” says Thomas Grolp, who is responsible for Intranet and Internet at Meier Tobler.

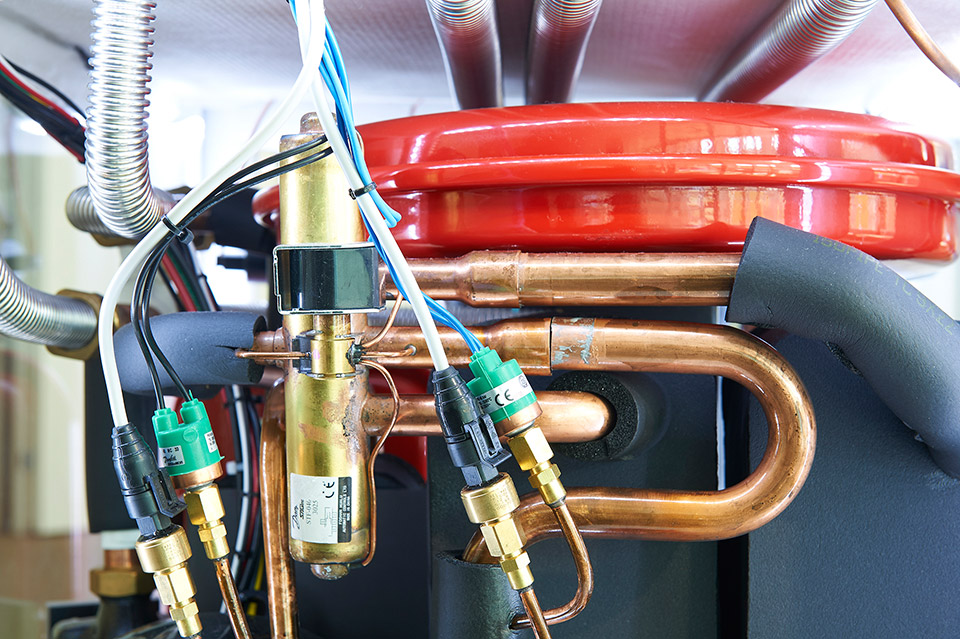

In addition to this, heat pumps as complex electromechanical systems can by no means manage without maintenance. Operating parameters must be optimally coordinated so that the heat pump will work efficiently and the service life can be extended. And it is also the case that defects can arise with such systems. Heat pumps require regular monitoring and optimisation as well.

In conversation with Thomas Grolp and Andreas Plüer.

Sit back and relax with “smart-guard”

“We want to offer customers an all-inclusive package – they shouldn’t have to worry about anything,” Grolp says, summing up the customer benefit of the new “smart-guard” service. The product name stands for a pioneering effort in terms of Industry 4.0: As Switzerland’s first company to do so, Meier Tobler is connecting the customer’s heat pump to its IT systems via an IoT platform, enabling remote diagnostics and remote maintenance. “If desired by the customer, we can put the heating system into power-saving mode during holidays, thus reducing energy consumption. This is included in the service package. In addition, twice a year customers receive a report with an evaluation of the past heating season.”

Andreas Plüer, Head of IT and Processes: “Much of an IoT project like smart-guard has nothing to do with technology, but with change.”

Currently some 300 service technicians visit a total of around 1000 customers each day. In the case of heat pumps, simple actions such as acknowledgement of an error message or changing a few parameters are often required. Such tasks can be taken care of just as well remotely, because modern heat pumps are equipped with appropriate sensors and controls that enable remote control. This means that special trips to the customer site would not always be necessary.

Andreas Plüer, Head of IT and Processes at Meier Tobler, names the first prerequisite for this: “The heat pump needs to get on the Internet.”

Meier Tobler saw itself confronted here with problems such as selecting suitable protocols, dealing with large data volumes and analysing the collected sensor data. “We realised that we needed to cooperate with competent partners,” Plüer says.

Successful IoT partnership

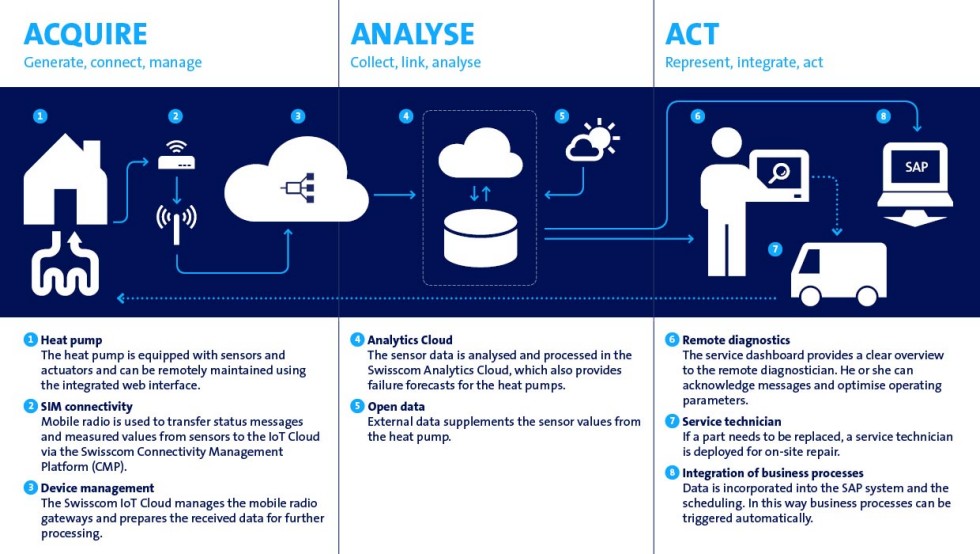

The principle of the three A's is the basis for successful IoT projects.

With Swisscom, Meier Tobler found a partner who seamlessly accompanies an IoT project from concept to operation – co-creation in the best sense. The solution follows the principle of the three As:

- “Acquire” (data collection from the heat pump)

- “Analyse” (evaluation and failure forecast)

- “Act” (remote diagnosis and remote maintenance)

In terms of technology, it relies on the innovative Industrial IoT solution from Swisscom: Using a mobile radio gateway with an antenna outside the heating-system room, the heat pump is connected to the Swisscom IoT Cloud, which ensures management of gateways and transmission of data to the Analytics Cloud. The heat pump data is combined with business data there and is also incorporated in Meier Tobler scheduling solution. The mobile data connection is controlled by the M2M platform CMP (Connectivity Management Platform) with coverage throughout Switzerland.

The remote diagnosticians have a web-based service dashboard at their disposal. They can check the operating status and gain insight into the state of wear of the system components, as Thomas Grolp explains: “Due to dependencies between the sensor values, an experienced technician can deduce that a fault is to be expected in the near future. For example, a constant pressure drop indicates a leak.” Using the web interface of the controller, parameters can be adjusted and error messages acknowledged. These tasks can be performed completely by remote diagnosticians. Only when a part needs to be replaced does the service technician need to visit the customer. Because of remote diagnostics, he or she is well prepared, can bring the right spare part and has no need to troubleshoot the error on site.

Thomas Grolp, Leiter Intranet & Internet, Meier Tobler (Klima Schweiz) AG: «Die Kunden erhalten zweimal jährlich einen Bericht über die vergangene Heizperiode».

The new job profile of remote diagnostician and the remote maintenance business model are associated with changes in the organisation and corporate culture. For Andreas Plüer, one of the main findings from the project is: “We quickly created a prototype, but turning it into a marketable product is a challenge. You quickly realise that much of this has nothing to do with technology, but with change.”

Thomas Grolp und Andreas Plüer am Eingang zum Hauptsitz von Meier Tobler.

Meier Tobler AG

Meier Tobler provides its trade partners with devices and installations for heating, air conditioning and ventilation. In 2015 the listed, family-dominated company achieved turnover of 240.7 million Swiss francs with 774 employees (in terms of full-time equivalents), of which 12 were trainees. A service organization of around 300 people ensures proper functioning of the installations throughout Switzerland.

Newsletter

Would you like to regularly receive interesting articles and whitepapers on current ICT topics?

More on the topic