Process efficiency thanks to data-driven business

Combined correctly, proven technologies offer genuine added value

There’s a new addition to the buzzword jungle: data-driven business. But why should this concept matter to you? Your business generates massive quantities of data. Data means information, opportunities and challenges, among other things. If you don’t make use of it, you’ll lose out in the long run. Yet the technologies for processing and analysing data to create added value are already here. So why not grab the opportunity and board the efficiency train? We’ll tell you why and, more importantly, how.

26 March 2019

What lies behind data-driven business? In short, a ‘data-driven’ company is one that either internally captures or externally obtains, then securely stores, processes, edits and analyses all the information generated as part of its business activities or that might prove useful. “Not many existing companies will become billion-dollar technology giants because of data. But every company can use data to help it grow, step by step,” says Urs Lehner, Head of Swisscom Enterprise Customers.

We’re not suggesting you completely abandon everything you have done before, launch a huge, disruptive project and become a data-driven business overnight. Rather, the motto we suggest you follow in order to become a digitised, data-driven company is ‘think big, start small’.

Think Big

We firmly believe that the data-driven business approach must today be incorporated in the tactical and strategic activities of any company that wants to remain competitive in the market. A company that does nothing with the vast amounts of data available will, in future, be like a car sitting on the hard shoulder with an empty petrol tank while everyone else whizzes past at full speed. Can you imagine automating certain processes?

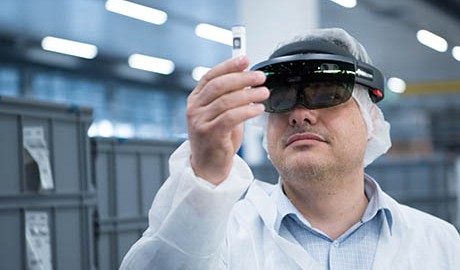

Feldschlösschen Getränke AG has used IoT technologies to connect its beer tanks and taps so everything can be monitored remotely. Current beer consumption is displayed on dashboards, so the tanks and beer glasses never run empty. Or maybe you can follow the lead of medical technology company Ypsomed and integrate your own 5G infrastructure. Thanks to the network, some of Ypsomed’s production phases are now automated. The possibilities are endless – you just need to start thinking outside the box.

Start Small

Not many companies have the time or resources to properly implement ground-breaking innovations overnight. Neither is it necessary. Virtually every company has hidden potential to become more efficient. It’s simply a case of finding it. Julian Dömer, Head of IoT at Swisscom, knows where to look. He wants customers to share with him their greatest challenges, their inefficiencies, their medium- and long-term objectives and how prepared they are to try new things: “Above anything else, the most important thing is to be prepared to do anything at all or to question the here and now,” says Dömer. Experience has shown that internal processes are a good place to start with initial projects: “Internal processes often have untapped potential. Efficiency or performance can be enhanced by connecting individual components, for example,” Dömer adds.

Julian Dömer, Head of IoT at Swisscom

The technologies and data are available and, with the right ideas, you can boost your efficiency in areas such as customer management, production, HR, accounting, logistics, etc. “The potential to gain an advantage is high wherever the same processes are repeated over and over again,” says Martin Gutmann, Head of Analytics & Data Consulting at Swisscom, emphasising the advice to ‘start small’.

The right combination makes it possible

By combining external and internal data, businesses can gain competitive advantages. Both data analysis and the monitoring and evaluation of customer behaviour are an important part of this. Demographic data (from social networks or market data, for example) must also be added to the pot. The functionalities that this requires are out of reach for traditional IT systems, which is why innovative technologies are necessary. A company that can view and adapt data in real time, and meet its customer’s needs quickly and flexibly, has become a data-driven business. But where do you start?

Start with a proof of concept

The palm tree in the header photo symbolises how something small can show how big the impact can be. Start realising your vision by taking calculable steps so it quickly becomes reality. You can use an initial proof of concept (PoC) to demonstrate the efficiency of an innovative new (internal) service so the idea of investing a large sum to implement the project can be either justified or abandoned. The key to realising a vision is to ask the right question in the first place, since a data-based project should ultimately produce a clear improvement in quality or concrete financial benefits. Swisscom experts are there to help: first of all to validate ideas, then to integrate and connect PoCs, and finally to help employees make use of the new possibilities in a way that adds value.

A PoC in only seven steps

With the right experts round the table, a common objective and understanding, mutual trust and cross-departmental, company-wide collaboration, we help our customers establish an initial proof of concept in seven steps:

- Introductory workshop

- Definition of strategic goals

- Planning of scope, budget and milestones

- Involvement of all relevant stakeholders

- Execution of PoC

- Testing and analysis

- Go-live

One company that we have helped take the first step to becoming a data-driven business with a PoC is Ypsomed, whose production process has been partly digitised using IoT and 5G. For example, product flows have been optimised by tracking boxes with sensors instead of scanning barcodes individually by hand. Manufacturing machines are also wirelessly connected and data analysed in real time. This enables Ypsomed to monitor production quality more or less in real time, which leads to much more cost-effective production processes. It also means Ypsomed can centralise and streamline its production more effectively than ever before.

More on the topic