Networked coffee maker

How the Internet of Things is improving coffee

Data makes better coffee. To put it bluntly, that’s the result of networked coffee machines. The Internet of Things provides the data infrastructure and makes it possible to build new service-oriented business models in combination with cloud, analytics and security solutions. Six good reasons to embrace ‘Barista 2.0’.

Text: Andreas Heer, 24 june 2019

Switzerland is a country of coffee lovers. Here, each of us drinks about three cups every day, which makes us number three in the world. But we don’t just drink a lot of coffee – we also celebrate barista culture. And there shouldn’t be any compromises when it comes to the quality of the coffee – even at work.

Drip makers and powdered creamer are a thing of the past. Vanilla latte, cappuccino, espresso macchiato... Today’s machines have to offer countless variations of the caffeinated brew. And foam prepared with fresh milk goes without saying.

A more enjoyable coffee experience thanks to sensors

Despite these high standards, the machine should also be functional at all times. After all, we wouldn’t want to go for that coffee we so look forward to when we hit our afternoon slump, only to find the machine is out of milk or needs servicing. This is why an ever-increasing number of sensors monitor the complex mechanisms inside modern coffee makers. Not only do they measure the level of milk and beans; they also check the condition of important components like the grinder. The machine also counts how many espressos, cappuccinos and other drinks have been dispensed and then sends all of this data to the manufacturer by way of the Internet of Things (IoT), which is made possible by a SIM card or eSIM. The data collected in the cloud is processed using new analytics tools and used for process automation, product improvement and new types of customer interaction.

Use customer insights to tap into new revenue streams

The combination of networking and data analytics opens up possibilities for completely novel applications and convenience features. Ironclad security included, of course. Cashless payment with smartphones and infotainment might be possible, too: in the future, the large displays on the coffee makers could show promotions, headlines, weather, mini-games, surveys and so on – all fully personalised. This could turn those 40 seconds while you wait for the drink to be made into an improved break experience and advertising opportunity, allowing the manufacturer to expand its business model and tap into additional revenue streams.

Less downtime thanks to predictive maintenance

Servicing tasks that cannot be completed remotely are time-consuming and costly. Using the data sent from the coffee maker, the manufacturer can anticipate which maintenance will need to be done, because they know the service life of each individual component. The effective duration or frequency of use allows them to determine when hoses or mechanical components such as the grinder need to be replaced. Ahead of time. This means that the service technician can plan the replacement before travelling to the customer. This kind of predictive maintenance saves time and avoids unnecessary trips, reducing the need for servicing. That means you can put away that ‘Out of order’ sign taped to the coffee maker for good. The service life of the machine that cost you have tens of thousands of francs on lasts longer as a result.

Predictive maintenance also mitigates Murphy’s Law: whenever demand is highest, the technician is sure to be working on the machine. Now, they can plan servicing for a time when coffee demand is lowest instead. The machines also provide manufacturers with the time data they need to make this judgement.

Optimising day-to-day business with real-time data

Milk and coffee beans have to be refilled during normal operations. The data on fill levels allows supply staff to know what work has to be done on which machines. And data-driven processes automate day-to-day business: ingredients are reordered automatically, and the ideal route can be determined based on the machine data and location information. This saves time for maintenance and servicing of the coffee makers, because service staff only have to go to the locations where actual work needs to be done.

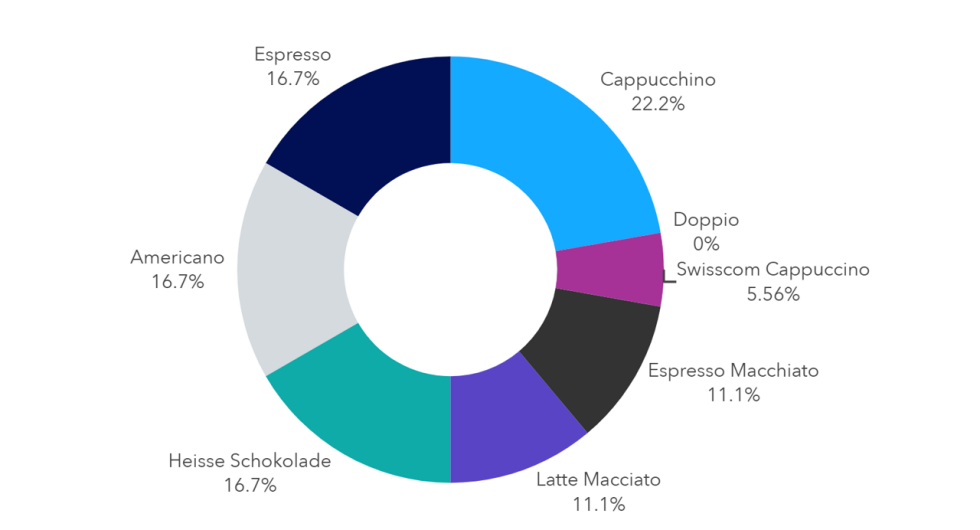

The simple coffee consumption analysis shows consumption statistics for each type of drink.

Improving coffee makers through experience values

In other words, the data from each individual unit indicates when maintenance is needed. But things get really interesting when the data from all coffee makers is combined. The aggregation of events allows manufacturers to identify weaknesses, such as poor hose connections, material problems or weak grinder motors. This information goes back into the further development of the product design.

The combined data also provides information about the service life of individual components. If experience values show that the machine’s grinder is approaching the end of its service life, the service technician can replace the part preventatively at a time when they will be servicing the machine anyway. This reduces downtime.

Better tasting coffee through data-driven technology

Coffee connoisseurs know that the grind, pressure and temperature all play an important role in the taste and quality of the drink. The manufacturer can make these adjustments remotely with firmware updates pushed out via IoT. This is done simultaneously for all coffee makers worldwide or those in a specific time zone. The benefit is obvious: instead of the service crew having to update each machine automatically and causing additional downtime, the update can be conveniently installed from a central system at the press of a button, outside of business hours.

Company employees benefit from these features whenever they go to the machine to get coffee, because now they are much more likely to see a range of selections rather than an error message. And based on the data collected, the manufacturer can better align the products to the tastes of its customers. And, ideally, employees will never even see the technician and instead enjoy the aroma of freshly brewed coffee whenever they happen to be in the mood. Mmm, now it’s time for a cup of really good coffee.

Data-driven business models

Swiss coffee machine manufacturers are pioneers in data-driven business, because consumers’ increasing standards are demanding the full transformation of analogue devices into digitalised products. The big industry names for professional coffee makers, Schaerer and Franke, are gradually networking their machines for professional use in restaurants and office buildings. New technology components, such as IoT, cloud, analytics and security not only create better devices; analysing the data is also making it possible to develop new lucrative service models and a greater customer focus. What applies to professional coffee makers is conceivable for every other type of machine or device.

Newsletter

Would you like to regularly receive interesting articles and whitepapers on current ICT topics?

More on the topic