We heat our buildings so we don’t freeze in cold weather. However, since most heating systems in Switzerland are still oil-fired, as room temperatures increase, so does the harm to the environment in the form of CO2 emissions. There is therefore a need for more efficient heating systems. The company Belimo recognised this and won second place in this year’s Swisscom IoT Climate Award.

How heating systems work

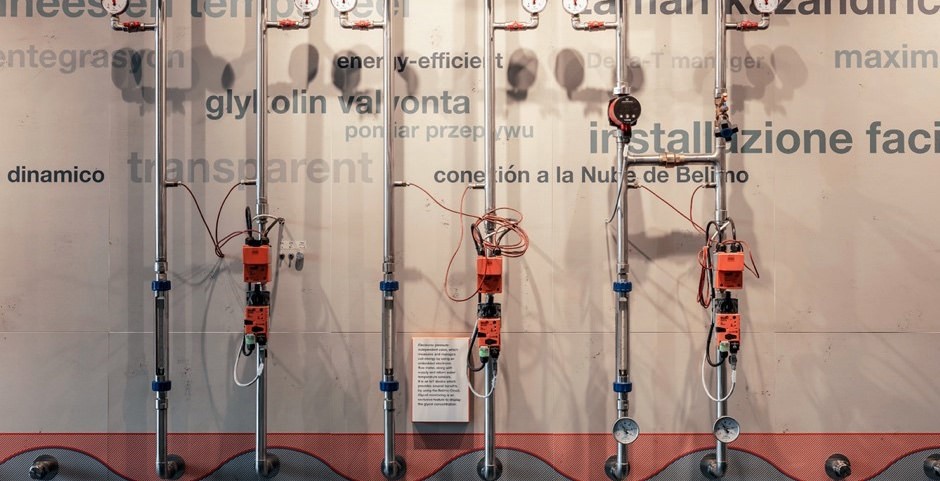

Using the Internet of Things (IoT), the Hinwil-based company ensures that buildings use less energy to keep room temperatures at the same level. It is important to understand the basics of how heating systems work: using an energy source – mainly heating oil currently – water is heated and pumped from the basement through heating pipes to radiators around the building. A valve on each radiator can be used to set the desired temperature. All clear so far? This is where Belimo comes into play. “The water needs to be pumped to the radiators on each floor at the right flow rate. This is set by a control valve, which dynamically regulates the flow rate as required, including at part load,” says Daniel Senn, Belimo’s business development manager. This dynamic hydraulic balancing process is extremely important, but is often not carried out, he says. On the contrary: “Static hydraulic balancing is always carried out at 100% full load, a situation that is extremely rare in reality,” explains Daniel Senn’s colleague, Rony Riedo, the company’s Swiss sales division manager.

31,055 tonnes fewer CO2 emissions

The water flow rate therefore needs to be optimised because this balancing process should really be carried out every time someone turns up the heating. This is the job of the Belimo Energy Valve™, which does it automatically. Daniel Senn explains: “The valve measures the temperature differences in the hot water and, if the difference is too small, it notices and makes the necessary adjustment.” Since 2012, this system has saved a total of 31,055 tonnes of CO2 worldwide. And the potential is huge, with buildings responsible for around 40% of global CO2 emissions.

But where does IoT fit in to all this? “One big problem that currently leads to inefficiency is the lack of data. Data is generally crucial for successful process optimisation,” says Daniel Senn. This is why the smart valves are connected to the cloud. A monitoring system can show which parts of a building the heat is flowing to and where it is being wasted. Rony Riedo explains: “Unlike our competitors, we offer fully integrated, free cloud access without the need for a subscription. You just buy the valves and everything else is included.”

Need for information

The savings on heating costs quickly add up, begging the question of why technical optimisation methods of this kind are not used in the heating systems of all new buildings. “It’s actually the developers who decide what to install. But most of them lack the technical expertise and aren’t even aware of the existence of these new, much more efficient systems,” says Daniel Senn. The developers therefore need to be better informed, while architects and designers should promote these new, efficient systems, he says. Rony Riedo adds: “We need more pilot projects where people can go and see it for themselves. There is still a lot of scepticism about cloud technology within the industry.”

Generally speaking, there is still not enough interconnection between individual IoT solutions. “We have already invested hugely in this cloud platform, which we will keep expanding. And we always try to stay one step ahead where technology is concerned,” says Rony Riedo. This idea is deeply rooted in the DNA of the company, which invests between 7% and 8% of its turnover in research and development.

Latest news about Swisscom

Subscribe to News

Contact us

Address

Swisscom

Media Relations

Alte Tiefenaustrasse 6

3048 Worblaufen

Postal address:

Postfach, CH-3050 Bern

Switzerland

Contact

Tel. +41 58 221 98 04

media@swisscom.com

Other contacts

Contributing to sustainability

SDG 7: reduced energy consumption to make buildings more energy-efficient.

SDG 11: more sustainable building management, enhanced well-being.

SDG 13: lower CO2 emissions thanks to reduced use of fossil fuels.